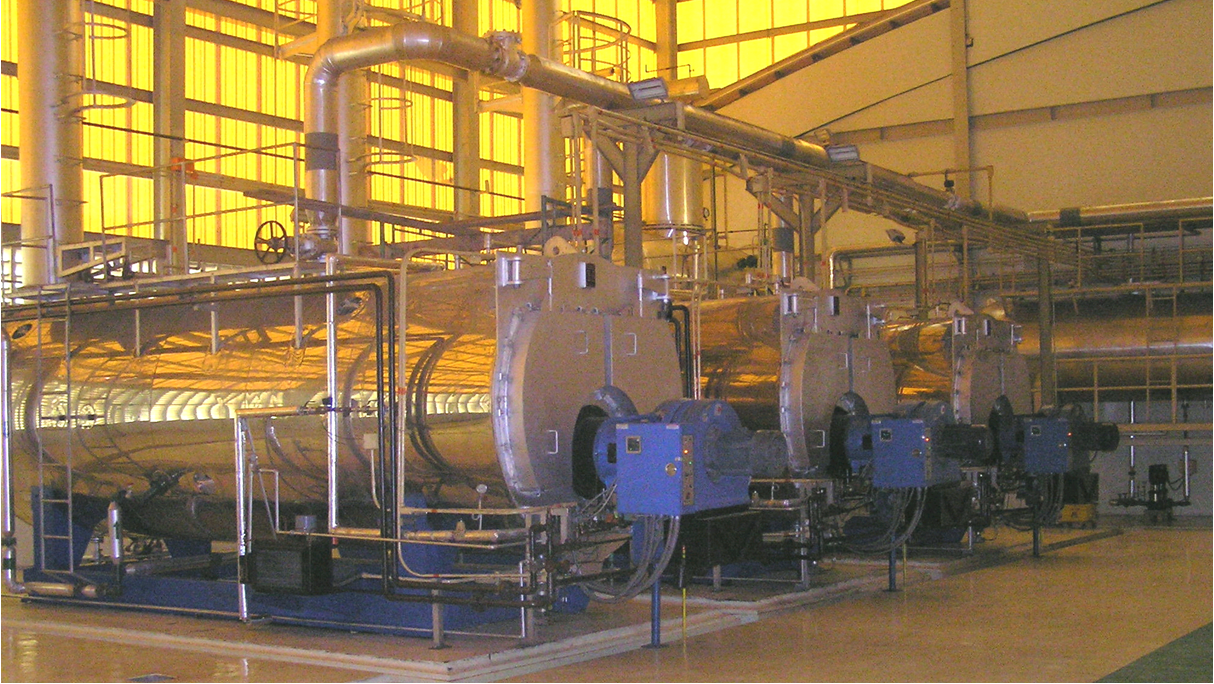

BRAM: Smarter Boiler, Smarter Decisions

BRAM integrates with a boiler’s PLC system to provide real-time data retrieval, analytics, and automated reporting.

For Manufacturing & Industrial End Users:

Real-time descriptive analytics track steam generation, pressure, and efficiency, while prescriptive analytics provide AI-driven recommendations for energy savings and boiler optimization. Predictive and preventative maintenance helps detect issues early, minimizing downtime and repair costs. Additionally, automated reporting ensures boiler operations remain safe and compliant with regulatory standards.

Key Differentiators:

- Seamless PLC Integration: Retrieves and processes data directly from boilers

- AI-Powered Insights: Transforms complex boiler data into actionable decisions.

- Energy Eciency Optimization: Reduces fuel consumption and operational costs.

- Predictive Maintenance Alerts: Prevents breakdowns and costly unplanned shutdowns.

- Compliance Automation: Keeps boiler operations within regulatory standards eortlessly.

Key Features

Core Capabilities that Drive Results

Real-Time Boiler Monitoring:

Track performance data to optimize steam usage.

AI-Powered Predictive Maintenance:

Detect issues before they cause breakdowns

Automated Reporting & Compliance:

Ensure regulatory adherence effortlessly.

Energy Efficiency Optimization:

Reduce fuel consumption and improve cost savings.

Seamless Cloud Integration:

Access insights anytime, anywhere

Upgrade your boilers with intelligence. BRAM ensures maximum efficiency,safety, proper documentation and profitability.

Industrial End-Users (Manufacturers, Hospitals, Power Plants, etc.)

Reduce fuel costs, optimize operations, and prevent boiler failures.

Operations & Maintenance Teams

Get automated reports and alerts to maintain peak boiler performance.

Owners, Executives & Plant Managers

Make data-driven decisions to enhance overall plant efficiency.